- Time:2019/1/10 Posted:联系我们果博东方有限公司客服电话19048888886(北京区客服)

In the automotive industry, parts processing from blank processing to assembly of the vehicle requires various processing techniques, so more than half of the investment in the automotive industry is used to purchase advanced manufacturing equipment. Let us walk into Audi's German factory to experience the charm of the automotive industry and see what kind of equipment and processes are used in the factory...

In recent years, the launch of new energy vehicles has brought new development directions to the entire industry. The automotive industry is shifting from internal combustion engines to alternative drives, and it is not surprising that some supply chain companies have seen earnings declines and weak growth expectations.

As a giant in the supply of flexible production lines for internal combustion engines, the German GROB Group has a market share of approximately 75% in the manufacturing of powertrains in China, and its flexible production lines can be seen in almost all OEMs. So, how can a German company that has achieved outstanding success in the traditional internal combustion engine market face new challenges in the automotive industry?

Recognize the trend and invest heavily in R&D transformation

“The shift of the automotive industry from internal combustion engines to alternative drive methods is not only an urgent need of our global customers, especially under the diesel issue, but also has a huge impact on our GROB Group. We must work together to transform and maintain an inclusive attitude towards this. The most important thing is that we don't have to be afraid of them. Because there is only one way, that is the way forward, the electric vehicle market will definitely provide GROB with broad market development prospects in the future.” Ren always regards the challenges of the automobile industry as one time. New opportunities.

Faced with far-reaching new challenges, the GROB Group recognized this trend very early, re-targeting the market and fully understanding the development and opportunities of the automotive industry. The most important is the development of new technologies. Significant investments have been made in a timely manner, so GROB can now easily meet OEM customer requirements for technology change and provide new customers with the services they need.

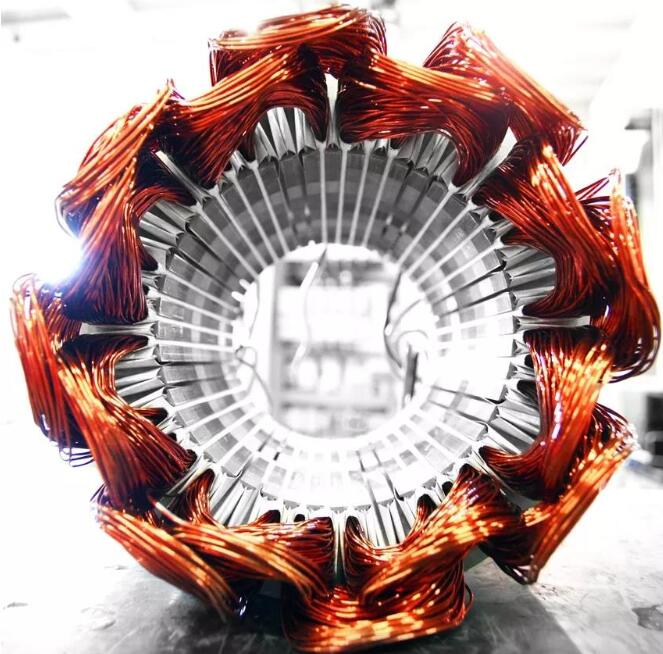

“Hairpin flat wire stator assembly line is unique to us. It provides turnkey projects for first-line automakers such as German Volkswagen and German BMW. Technical strength, innovation capability and quality assurance are the advantages of our GROB; New energy vehicle drive motor is represented by multi-line and around stator winding production line and motor assembly line, as well as EPS motor, chute motor production line is GROB's specialty, with a number of patented technology guarantee." According to the general introduction, Laubo has made many new achievements in the field of electric vehicles. The latest Hairpin motor assembly line production technology has been exhibited for the first time at CWIEME Shanghai Exhibition in 2018. In March 2019, GROB will continue to bring the latest products and products at this exhibition. Technology debut.

Continue to consolidate the leadership position of traditional markets

Not only does the emerging electric vehicle market develop well, but in 2018, GROB China also received a number of important orders from the traditional business sector. Among them, at the end of 2018, Graub will deliver one of the new customers to Hanlong, a turnkey production line of cylinder heads completely produced by GROB China, including a total of 28 new Graubo sixth generation G Series machining center. Another new customer project is delivered to Changan Ford Motor Company. The eight sixth-generation G-series machining centers in this turnkey project are also produced independently by GROB China. It is important to emphasize that this project is the first to operate with two robots in a logistics buffer station, which functions like two small fully automated assembly stations. There is also a representative large order from Volkswagen Automatic Transmission (Dalian) Co., Ltd., which includes 11 fully automatic and 24 manual assembly stations, which will continue to expand the assembly line and electric vehicle business for the next stage of GROB China. A good foundation.

Open up new market areas

In addition to continuing to consolidate and expand its leading position in the automotive industry, GROB continues to explore new market segments such as aerospace, tooling, machinery manufacturing, and not just relying on an industry. The GA350 and GA550 are GROB's five-axis linkage universal machining centers specially developed for the Asian and Chinese markets. The predecessor was the Glaubo Group's highly successful and prestigious G350 and G550. The machine has been adjusted to operate in accordance with the needs of the Asian region, made in China, produced in Dalian, and continues the high quality of Germany.

The GA350 and GA550 have many advantages and features that can be used in all walks of life, such as: five-axis simultaneous processing while maintaining the perfect balance and extreme rigidity, easily processing the more difficult points. Fully automatic machining without conflicts makes it possible to use shorter tools, optimum chip removal to avoid failure due to chip residue, and high-precision machining of different materials with only one machining concept, even Pallet automation can be achieved without a pallet change system, etc.

At present, the GA series five-axis linkage universal machining center has conquered more and more customers from aerospace, tool and die, machinery manufacturing and other fields. Mr. Ren said that GA series sales have achieved a large leap-forward growth in 2017-2018, and will continue to maintain this momentum in 2019. On the basis of consolidating the original market share of system machine tools and automated turnkey projects, Develop new customer groups.

Expand production base to escort for further growth

The production base of GROB China in Dalian started production in 2012, which is the fourth production base in the world set up by the German GROB Group. With this high-tech production base with many advanced processing technologies, the GROB Group not only strengthens its business strength in the Chinese market, but also enhances its strategic positioning throughout the Asian economic growth region and ensures its long-term global competition. force.

In May 2018, GROB China's Dalian production base began the second expansion project, which will be completed in the first quarter of 2019. The modified and expanded facilities are multi-functional, and all types of GROB products can be assembled in the expanded 6,700 square meters production area. The expansion of GROB's Dalian production base is also gradually laying the foundation for the assembly line business until the mid-term electric vehicle field, which can provide localized production and service to Chinese customers and better promote the GROB Group's electric vehicles in China. The development of related businesses.

In addition to the expansion, GROB has also invested in Dalian Jinpu New District, adding 40,000 square meters of land, creating a prerequisite for further business expansion and company growth.

As the headquarters of the GROB Group in China, GROB Machine Tool (China) Co., Ltd. is based in Dalian, China with its brand-new identity and appearance. All future businesses will use this as a starting point to bring together Beijing and Shanghai. Sales and after-sales service branches, covering the whole of China and even Asia.